Fax: +86-519-86518620

1. Use and scope of application

DJ, DJ II large dip angle conveyor with corrugated sidewall belt is able to continuously transport bulk material by a large angle. It can transport bulk material with density ranging from 500 to 2500kg/m3, and is widely applied to various industries including metallurgy, mine, coal, construction material, chemical engineering, light industry, harbor, food, shipping, etc.

This conveyor is applicable to operation environment with temperature around -25℃~40℃. With corresponding protective measures applied, it can also operate under conditions with special requirements, such as explosion-proof, waterproof, fire-retardant, corrosion/high temperature/cold resistant.

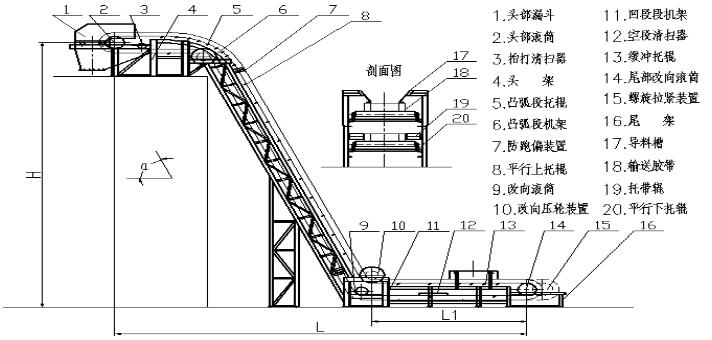

2.Technical features and structure diagram

|

Belt width (mm) |

Flange height (mm) |

Maximum transport quantity (m3/h) |

Dip angle(°) |

Belt velocity (m/s) |

Belt width (mm) |

Flange height (mm) |

Maximum transport quantity (m3/h) |

Dip angle(°) |

Belt velocity (m/s) |

|

400 |

60 |

28 |

30° ~ 90° |

0.8-2.0 |

1000 |

200 |

518 |

30° ~ 90° |

1.0-2.5 |

|

80 |

54 |

240 |

708 |

||||||

|

120 |

94 |

1200 |

160 |

702 |

1.0-3.15 |

||||

|

500 |

80 |

78 |

0.8-2.0 |

200 |

788 |

||||

|

120 |

104 |

240 |

1077 |

||||||

|

160 |

130 |

1400 |

200 |

942 |

1.0-3.15 |

||||

|

650 |

80 |

118 |

0.8-2.0 |

240 |

1329 |

||||

|

120 |

156 |

300 |

1613 |

||||||

|

160 |

210 |

400 |

2457 |

||||||

|

800 |

120 |

248 |

0.8-2.5 |

1600 |

200 |

1118 |

1.0-3.15 |

||

|

160 |

340 |

240 |

1578 |

||||||

|

200 |

370 |

300 |

1934 |

||||||

|

1000 |

160 |

465 |

1.0-2.5 |

400 |

2961 |